#LED display PCB

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/semiconductors--optoelectronics--leds/sml-lx0404siupgusb-lumex-5003908

PCB Surface Mount LED, High Power Optoelectronics, Led display screen,

Red/Green/Blue 0404 120° Water Clear 30/40/20 mcd PCB Surface Mount LED

#Optoelectronics#LEDs#SML-LX0404SIUPGUSB#Lumex#Isolation components#Light emitting diode#Light-emitting diode#laser led#PCB Surface Mount LED#High Power#Led display screen#Programmable led display

1 note

·

View note

Text

https://www.futureelectronics.com/p/semiconductors--optoelectronics--leds/sml-lx0603gw-tr-lumex-7962061

Optoelectronic devices, Isolation components, led display screen, led emitter

Green 0603 1.6 x 0.8 mm 160° Diffused 18 mcd 2.2 V PCB Chip Surface Mount LED

#Lumex#SML-LX0603GW-TR#Optoelectronics#LEDs#light control#optoelectronic applications#light emitting diode#Isolation components#led display screen#led emitter#Power Optoelectronics#PCB Chip Surface Mount LED#led monitor

1 note

·

View note

Text

https://www.futureelectronics.com/p/semiconductors--optoelectronics--leds/sml-lx0404siupgusb-lumex-5003908

Blue light-emitting diode, organic light emitting diode, Led display screen, led

Red/Green/Blue 0404 120° Water Clear 30/40/20 mcd PCB Surface Mount LED

#Optoelectronics#LEDs#SML-LX0404SIUPGUSB#Lumex#devices#PCB Surface Mount LED#light emitting diode Blue light#organic light emitting diode#Led display screen#digital led#led display programming Outdoor led display lighting#led display

1 note

·

View note

Text

Schlatt: Now what did you get? What did Santa bring you?

Charlie: I got— Okay, yeah, the big questions. I got… Yknow what? Why don’t I just show you.

Ted: While we’re waiting, Schlatt, you have a good Christmas? Keep it short.

Schlatt: Yeah.

Charlie: Keep them entertained, guys!

Schlatt: I got a— because, yknow, I am far from home. Like that Spider-man movie or some shit.

Ted: Okay.

Schlatt: I was gifted a little like PCB board that had tiny little LEDs that map every subway station in the New York City metropolitan area.

Ted: Oh, that’s cool.

Schlatt: And it connects to WiFi and it pulls like the subway data from the MTA site.

Ted: Oh my god.

Schlatt: And it, in real time, it displays on the map where all the subways are. Oh my god. That is much cooler than my fucking gift, Charlie. Holy shit.

Ted: Holy shit.

Charlie: Do you like this? Look at that. It says “Oh Snap”.

Ted: Wow.

Schlatt: Disregard anything I ever said. Oh my goodness.

Ted: Yeah, Schlatt, whatever you said it’s just fucking…

Chalice: Look at that.

Ted: Oh.

Charlie: Check this out. Check this out.

Ted: Wow.

Ted: So, first time I’m gonna say this in the new year, audio listeners, love you to death. Charlie is wearing a gorgeous, glorious,

Charlie: Look at it catch the light there. Do you see that?

Ted: Oh Christmas sweater.

Charlie: Look at it catch the light.

Schlatt: Christmas sweater with— sleeveless.

Ted: Sleeveless Christmas sweater.

Charlie: Barely a sweater.

Ted: Sleeveless with frills around where the sleeves are cut off. He’s dancing.

Charlie: And even down here a little…

Ted: Wow. This is incredible.

Charlie: Doing a little Christmas jingle.

Ted: Oh my goodness.

93 notes

·

View notes

Text

Festival of Lights - Night #8 Tiny Round 0.7" TFT Display 💡🎉

It's the last night of our "Festival of Lights" mega design fest—to wrap up this year, we're doing eight days of light-filled designs!

We started with the Sparkle Motion Mini

) which can drive thousands of shimmering RGB LEDs. Then, we did the Sparkle Motion stick, a USB-pluggable version (

). On the third night, a 1.28" round TFT display (

), and on the fourth, a 1.8" round TFT with captouch overlay (

). On the fifth night, a tiny 0.85" TFT display (

) came to life. We took a little break on the sixth night since we were doing a lot of Sparkle Motion testing (

) and did a quick revision of our NeoRGB (

) The seventh night was a transparent OLED display with 128x64 pixels and an I2C interface. (

Tonight - the candles are burned out, the donuts are all eaten, and the final prototype PCB is booked! This is a mini breakout for a tiny 0.7" round TFT display with 160x160 pixels. What is this, a display for ants? We couldn't fit a micro SD card socket on the back, but we did get an EYESPI socket on there, and 0.1" spaced breakout pads with all the necessary connections, plus a regulator and level shifter. Whew, we're going to bed - Happy New Year!!!

#festivaloflights#night8#tftdisplay#electronicsdesign#tinytech#makersgonnamake#diyelectronics#ledlove#sparklemotion#rounddisplay#tftscreen#microcontrollers#adafruit#techfest#electronicsprojects#hardwaredesign#prototyping#smallbutmighty#newyearprojects#eyespitft#donutsanddesigns#lightfestival#pcbsuccess#techinnovation#openhardware#creativeengineering#happynewyear2025#tinytechmarvels#designwrapup

10 notes

·

View notes

Text

4x4x4 PCB LED CUBE

youtube

Bring life to your home with this enchanting 4x4x4 LED cube. From static to flashing, chasing, or fading this cube can be programmed to display many different types of 3D LED transitions. This customizable PCB LED cube is super easy to make and fun to have in your home. Go ahead and create a forest of these cubes using various color LEDs to enhance the beauty of your Christmas Tree this Christmas. This cube has 64 Blue LEDs organized in 4 layers. These LEDs are wired up to an Arduino Nano. Each LED can be addressed individually using Arduino IDE, enabling it to display amazing 3D transitions! There are hundreds of tutorials of these cubes made using exposed metal wires and by using crazy soldering techniques, which just gives me shivers. In this tutorial I'll show you guys how to make this super simple 4x4x4 PCB LED cube "without over complicating anything". With just basic soldering skills, you can create this PCB cube and light up your living room making everyone jealous.

3 notes

·

View notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

GIGABYTE Introduces AMD Radeon RX 7600 XT 16GB GPU

GIGABYTE TECHNOLOGY releases an AMD RDNA 3 graphics card today. GIGABYTE’s best-in-class WINDFORCE cooling system comes with the AMD Radeon RX 7600 XT GAMING OC 16G graphics card. Its superior performance, stunning visual effects, and efficiency make it ideal for 1080p gaming and streaming.

GIGABYTE AMD Radeon RX 7600 XT Gaming Performance

With its three distinct blade fans that spin alternately, its composite copper heat pipes that come into direct contact with the GPU, its three 3D active fans, and its screen cooling, the GIGABYTE WINDFORCE cooling system is designed with gamers in mind. By rotating the central fan in the opposite direction from the side fans, the Alternate Spinning technology directs airflow in the same direction, doubling air pressure and lowering turbulence. This design improves overall cooling performance by efficiently dissipating heat from the graphics card’s top and bottom.

Using graphene nano lubricant, three of the WINDFORCE fans have a 2.1-fold longer lifespan than the double ball bearing design, with a quieter operation that nevertheless yields nearly the same durability. The protective back plate keeps the PCB from bending or getting damaged in addition to strengthening the graphics card’s overall structure. With customizable LED lighting on the side that can be displayed in a personalized manner using software, the graphics card boasts a gaming-style design.

The graphics card’s superior performance can be attributed to its power design and utilization of ULTRA DURABLE certified components. With their superior computational performance and extended lifespan, ULTRA DURABLE certified high-quality materials like metal chokes, all-solid capacitors, and low-resistance MOSFETs allow gamers to fully immerse themselves in 1080p gaming and vivid virtual worlds.

The 16GB of GDDR6 memory and next-generation technologies that enable a smoother, better-looking, and ultra-fast gaming experience at 1080p and beyond give the GIGABYTE AMD Radeon RX 7600 XT GAMING OC 16G graphics card the promise of great gaming for years to come. You can adjust your game settings to achieve the highest level of immersion and responsiveness, and in certain crucial situations, you can even increase the resolution to 1440p, thanks to next-generation technologies like AMD FidelityFX Super Resolution 3 and AMD HYPR-RX with AMD Fluid Motion Frames.

With 16GB of lightning-fast RAM, games will be ready for years to come, and workloads involving creation and Al can be completed with greater freedom and inventiveness. Future-ready performance and next generation technologies are what gamers care about most, and the GIGABYTE AMD Radeon RX 7600 XT GAMING OC 16G graphics card delivers on both fronts.

Read more on Govindhtech.com

#GIGABYTE#AMDRadeonRX7600XT#16GBGPU#AMDRDNA3#graphicscard#WINDFORCE#RAM#technews#technology#govindhtech#gpu

2 notes

·

View notes

Text

Building a pc has taught me a great horror: motherboards do not have a speaker in them for debugging/troubleshooting anymore; they beep error codes, but you gotta get a speaker separately to hear it. The boards with good debugging features - a seven segment digit display for error numbers you can look up in the manual - cost around us$500 and come with a bunch of random bullshit you don't need or don't even want (unavoidable and easily exploitable bloatware, LEDs up your ass, a dozen Sata ports when you'll probably only use one or two at most, so much VRM cover that you can't see or check important parts of the pcb...). I have already become The Joker.

#rambling#It's a miracle we still got those four light indicators for DRAM/CPU/BOOT/VGA but they are so unspecific#Most of the time you'll get an error in either DRAM or CPU (or both at once!) and those could be caused by virtually anything#Even things unrelated to your RAM or CPU#The CPU light making people shit their pants#Rant brought to you by me having some kind of problem with DRAM that i hope will be resolved by just buying new ram sticks

6 notes

·

View notes

Text

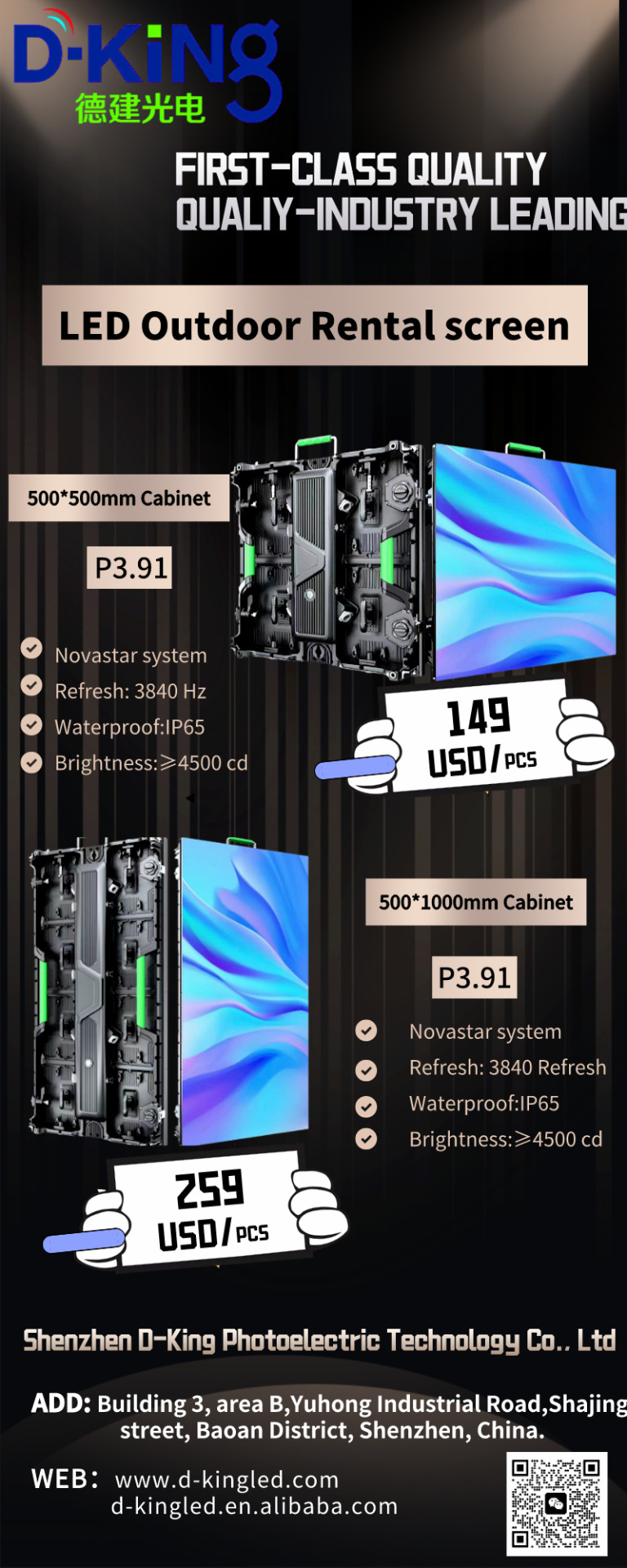

LED rental display, factory direct sales, price concessions. →Model: P2.604/P2.976/P3.91/P4.81. → Module size: 250250mm. → Cabinet size: 500500mm/500*1000mm. → Lamp: SMD1415/SMD1921 copper lamp. →PCB: 1.6mm thick flame retardant 4 layers circuit board. → Receiving card: Novastar system. → Refresh: 3840 Refresh → Power supply: 5V 40A 200W. ………………………

WhatsApp: +86 18819048581

3 notes

·

View notes

Text

"Heron" hardware MIDI sequencer (work in progress) - 2023 Built with: - Raspberry Pi 4B - 4.3" DSI Touch Display - Midiface 4x4 USB MIDI interface - Custom PCB and various switches/encoders/GPIO expanders/LEDs/... - Shell, Python and Node.js The UI is built with Electron and React. The previous version of the UI used node-raylib - which has less overhead and is more performant, but developing in a browser window is much faster. The quad-core RPi seems to be able to handle it without too much latency. The Electron app communicates with the Python processes for IO access and shared state is stored in memory using Redis.

2 notes

·

View notes

Text

5-Hydroxymethylfurfural (5-HMF) Market Report: Innovation, Growth & Strategic Forecasts

🧪 What’s Inside the Report?

The 5-HMF Market Report offers an in-depth look into market trends, size, growth drivers, and emerging strategies. It explores how major companies are innovating and adapting post-COVID, with a focus on revenue trends, CAGR projections, and long-term market positioning.

💡 Key Insights Covered:

📈 Market size, share & growth rate

🔍 COVID-19 impact & recovery strategies

💼 Business strategies from key players

🧫 Segmentation: Inline 3D AOI, Offline 3D AOI

🖥️ Applications: PCB Industry, Panel Display Industry

🌐 Global analysis across North America, Europe, APAC, MEA, Latin America

🏢 Top Companies Featured:

GÖPEL electronic GmbH

Omron Corporation

Koh Young Technology

Viscom

Saki Corporation

ViTrox Corporation Berhad

Nordson YESTECH

Test Research, and more!

📥 Get a Free Sample Copy 📘 Explore Full Report Here

❓ Key Questions Answered:

What is the forecasted growth rate of the 5-HMF market?

What trends and innovations are shaping the industry?

Who are the leading players, and how are they performing?

What are the opportunities, risks, and regional trends?

📌 Best For:

Chemical industry analysts 🧬

PCB & electronics manufacturers 🖨️

Strategic investors 📊

R&D professionals & academic researchers 🧑🔬

📚 Discover More Industry Reports:

Bone Conduction Headphones Market

Cannabis Packaging Market

LED Glass Market

Microfluidic Chips Market

#🌍#5HMFMarket#ChemicalIndustry#SmartManufacturing#Electronics#PCBTrends#PostCOVIDRecovery#BusinessForecast#IndustryResearch#SustainableChemicals#B2BInsights#TumblrBiz

0 notes

Text

Boost Charge Pump ICs Market to Reach $1.5 Billion by 2032 at 7.8% CAGR

MARKET INSIGHTS

The global Boost Charge Pump ICs Market was valued at US$ 834 million in 2024 and is projected to reach US$ 1.5 billion by 2032, at a CAGR of 7.8% during the forecast period 2025-2032.

Boost charge pump ICs are voltage-boosting integrated circuits that provide efficient power conversion without requiring bulky inductors. These compact ICs utilize capacitor-based charge pumping techniques to step up input voltages, making them ideal for space-constrained applications like mobile devices, wearables, and IoT electronics. The technology offers advantages including low component count, reduced board space requirements, and simplified design implementation compared to traditional boost converters.

The market growth is driven by expanding demand from the consumer electronics sector, particularly smartphones and portable devices requiring efficient power management solutions. Additionally, the automotive industry’s increasing adoption of electronic systems and the proliferation of IoT devices are contributing to market expansion. Recent innovations focus on improving conversion efficiency – for instance, Texas Instruments introduced a 94%-efficient charge pump in 2023 for smartphone displays. Key players like Analog Devices, Microchip Technology, and Monolithic Power Systems dominate the competitive landscape with extensive product portfolios.

MARKET DYNAMICS

MARKET DRIVERS

Proliferation of Portable Electronics to Fuel Demand for Boost Charge Pump ICs

The exponential growth in portable electronics, including smartphones, tablets, and wearables, is significantly driving the boost charge pump ICs market. These ICs provide efficient voltage conversion in compact form factors, making them ideal for space-constrained mobile devices. With global smartphone shipments exceeding 1.2 billion units annually and the wearables market projected to maintain a 15% CAGR through 2030, manufacturers are increasingly adopting charge pump solutions for their power management needs. The ability to operate without bulky inductors gives boost charge pump ICs a distinct advantage in modern electronics design, where minimizing PCB footprint is critical for product differentiation.

Automotive Electrification Trend to Accelerate Market Expansion

The automotive industry’s rapid transition toward electrification is creating substantial opportunities for boost charge pump IC manufacturers. Modern vehicles incorporate over 100 power rails requiring efficient voltage regulation, from infotainment systems to advanced driver assistance systems (ADAS). With electric vehicle production expected to surpass 30 million units annually by 2030, the demand for compact power conversion solutions is intensifying. Boost charge pump ICs are particularly valuable in automotive applications due to their inherent noise immunity – a critical factor in EMI-sensitive environments. Tier-1 suppliers are increasingly specifying these components for lighting systems, display backlights, and sensor arrays where traditional boost converters would introduce unwanted electromagnetic interference.

MARKET RESTRAINTS

Power Density Limitations to Constrain High-Current Applications

While boost charge pump ICs offer compelling advantages for low-power applications, their inherent architecture creates challenges for higher current implementations. The capacitive nature of charge pumps makes them less efficient than inductor-based solutions when output currents exceed approximately 250mA. This limitation restricts their use in power-hungry applications such as high-brightness LED drivers or motors, where switching regulators remain dominant. As electronic systems continue demanding more power in smaller form factors, manufacturers face engineering challenges in pushing charge pump technology beyond its traditional boundaries.

MARKET CHALLENGES

Thermal Management Issues in Compact Designs

Thermal performance poses a significant challenge for boost charge pump IC adoption in advanced applications. The switching nature of charge pumps generates internal heat that must be dissipated, particularly in sealed enclosures common to modern consumer electronics. Unlike inductor-based converters where heat spreads across multiple components, charge pump designs concentrate thermal loads in the IC package. This becomes increasingly problematic as device footprints shrink below 2mm x 2mm, creating hot spots that can affect reliability and lifespan. Manufacturers are investing heavily in advanced packaging technologies and thermal-aware layout techniques to address these limitations while maintaining competitive pricing.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Avenues

The explosive growth of IoT devices presents a substantial expansion opportunity for boost charge pump IC manufacturers. With over 75 billion connected devices projected by 2025, the need for ultra-low-power voltage conversion solutions is becoming critical. Charge pump ICs are particularly well-suited for energy harvesting applications powering wireless sensors and edge devices, where their quiescent currents below 1μA significantly extend battery life. Recent advancements in capacitive boost architectures now enable efficient operation from input voltages as low as 0.7V, opening new possibilities for photovoltaic and thermoelectric energy harvesting implementations. Market leaders are actively developing application-specific variants optimized for these emerging use cases.

BOOST CHARGE PUMP ICS MARKET TRENDS

Growing Demand for Compact Power Management Solutions Drives Market Expansion

The global boost charge pump ICs market is witnessing robust growth due to increasing demand for compact and efficient power management solutions in portable electronic devices. These ICs offer significant advantages over traditional boost converters, requiring fewer external components and eliminating bulky inductors. Major semiconductor manufacturers reported a 15-20% year-over-year growth in charge pump IC shipments in 2023, primarily driven by smartphone manufacturers integrating these components for display backlighting and camera flash applications. The shift towards 5G-enabled devices, which require multiple voltage rails in compact form factors, has further accelerated adoption. Furthermore, automotive applications are emerging as a high-growth segment, with electric vehicle manufacturers increasingly incorporating these ICs for LED lighting and infotainment systems due to their electromagnetic interference (EMI) benefits.

Other Trends

Advancements in IoT and Wearable Technology

The proliferation of IoT devices and wearables is creating new opportunities for boost charge pump IC manufacturers. These applications demand ultra-low-power operation with minimal board space requirements, precisely the strengths of modern charge pump designs. Recent technological innovations have enabled charge pumps to achieve efficiencies above 90% even at low output currents, making them ideal for always-on sensor applications. The wearable device market, projected to exceed 1 billion units annually, represents a particularly promising segment where the size and efficiency advantages of charge pumps provide competitive differentiation for product designers.

Industry 4.0 and Smart Factory Adoption

The ongoing digital transformation in manufacturing is driving demand for boost charge pump ICs in industrial automation applications. Smart factory implementations require numerous distributed sensors and actuators, many of which need small footprint power solutions with reliable performance. Charge pump ICs are increasingly being specified for factory automation equipment because their inductorless design makes them inherently more resistant to vibration and mechanical stress compared to switching regulators. The industrial segment now accounts for approximately 20% of total charge pump IC revenue, with annual growth rates exceeding the overall market average due to accelerated Industry 4.0 adoption across major manufacturing economies.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Expansion Drive Market Leadership in Boost Charge Pump IC Segment

The global boost charge pump IC market exhibits a semi-consolidated structure with prominent players competing through technological advancements and strategic collaborations. Analog Devices and Texas Instruments currently dominate the landscape, collectively holding over 30% of the 2024 market share due to their comprehensive portfolios spanning industrial, automotive, and consumer electronics applications.

The Asia-Pacific region has witnessed aggressive growth from domestic manufacturers like Silergy Corp. and SG Micro Corp., who are gaining traction through cost-optimized solutions for mid-range applications. Their success stems from vertical integration capabilities and strong regional supply chain networks that reduce time-to-market for new designs.

Recent strategic movements highlight the industry’s dynamism. Monolithic Power Systems expanded its charge pump offerings through the 2023 acquisition of a specialty analog design firm, while Microchip Technology strengthened its position in automotive applications through partnerships with Tier-1 EV manufacturers. Such consolidation activities are reshaping competitive positioning across the value chain.

Emerging players face challenges in matching the R&D budgets of industry leaders, many of whom invest 15-20% of annual revenues in product development. However, niche specialists like ABLIC Inc. demonstrate how focused innovation in ultra-low-power designs can carve sustainable market positions, particularly in IoT and wearable segments.

List of Key Boost Charge Pump IC Companies Profiled

Analog Devices, Inc. (U.S.)

Texas Instruments Incorporated (U.S.)

ABLIC Inc. (Japan)

Torex Semiconductor Ltd. (Japan)

Shanghai Awinic Technology Co., Ltd. (China)

Southchip Semiconductor Technology Co., Ltd. (China)

Silergy Corp. (China)

Halo Microelectronics Co.,Ltd. (China)

Wuxi Hexin Semiconductor Co., Ltd. (China)

Meraki Integrated Shenzhen Technology Co., Ltd. (China)

SG Micro Corp. (China)

Microchip Technology Inc. (U.S.)

Monolithic Power Systems, Inc. (U.S.)

Qualcomm Inc. (U.S.)

Segment Analysis:

By Type

Capacitive Adjustable Charge Pump ICs Gain Traction Due to Voltage Flexibility in Compact Designs

The market is segmented based on type into:

Switching Regulator Booster Pump ICs

Capacitive Non-Adjustable Charge Pump ICs

Capacitive Adjustable Charge Pump ICs

By Application

Mobile and Consumer Electronics Leads Market Owing to Proliferation of Portable Devices

The market is segmented based on application into:

Mobile and Consumer Electronics

Industrial

Automobile and Rail Transit

Telecommunications and Infrastructure

Medical

Regional Analysis: Boost Charge Pump ICs Market

North America The North American Boost Charge Pump ICs market is characterized by strong technological adoption and demand from key sectors like consumer electronics, automotive, and industrial automation. The U.S. dominates regional revenue, fueled by extensive R&D investments from semiconductor giants such as Texas Instruments and Analog Devices. Regulatory frameworks supporting energy efficiency, such as DOE standards, drive innovation in power management solutions. Notably, the growing adoption of IoT devices and portable electronics has boosted shipments—estimated at 78 million units in 2023. However, supply chain disruptions and trade restrictions on semiconductor imports pose challenges for smaller manufacturers.

Europe Europe’s market thrives on stringent energy-efficiency mandates (e.g., EU Ecodesign Directive) and demand from automotive electrification. Germany leads in industrial applications, while France and the U.K. show growing uptake in telecommunications infrastructure. The region favors capacitive adjustable charge pump ICs for precision voltage control. Collaborative initiatives like the European Chips Act aim to reduce dependency on imports, fostering local production. Nonetheless, high manufacturing costs and competition from Asian suppliers restrain market expansion, pushing firms toward niche applications like medical devices.

Asia-Pacific Accounting for over 40% of global demand, Asia-Pacific is the fastest-growing market, driven by China’s electronics manufacturing dominance and India’s expanding consumer tech sector. China’s semiconductor self-sufficiency push (e.g., “Made in China 2025”) has elevated domestic players like Silergy Corp. and Southchip Semiconductor. Japan and South Korea contribute through automotive and display driver applications. Cost-sensitive markets prefer capacitive non-adjustable variants, though urbanization and 5G deployment are shifting demand toward higher-efficiency ICs. Challenges include intellectual property concerns and fluctuations in raw material pricing.

South America South America remains an emerging market, with growth hindered by economic instability and fragmented supply chains. Brazil’s automotive industry, however, presents opportunities for Boost Charge Pump ICs in infotainment and ADAS systems. Local assembly plants increasingly source components from Asian suppliers due to affordability. The lack of robust semiconductor infrastructure limits high-volume adoption, though government incentives for electronics manufacturing (e.g., Brazil’s “Lei do Bem” tax credits) show long-term potential.

Middle East & Africa This region shows nascent but promising demand, primarily in telecommunications and renewable energy projects. The UAE and Saudi Arabia lead in infrastructure development, integrating charge pump ICs into solar inverters and smart grid systems. South Africa’s automotive sector also presents niche opportunities. While market maturity lags due to limited local expertise and reliance on imports, partnerships with global suppliers and gradual industrialization could accelerate growth in the next decade.

Report Scope

This market research report provides a comprehensive analysis of the Global Boost Charge Pump ICs Market, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global Boost Charge Pump ICs market was valued at USD 312.5 million in 2024 and is projected to reach USD 487.2 million by 2032, growing at a CAGR of 5.7%.

Segmentation Analysis: Detailed breakdown by product type (Switching Regulator Booster Pump ICs, Capacitive Non-Adjustable Charge Pump ICs, Capacitive Adjustable Charge Pump ICs), application (Mobile and Consumer Electronics, Industrial, Computer, Automobile and Rail Transit, Telecommunications and Infrastructure, Medical), and end-user industry.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific accounted for 42% of the global market share in 2024.

Competitive Landscape: Profiles of leading market participants including Analog Devices, Texas Instruments, ABLIC Inc., and Microchip Technology Inc., covering their product portfolios, market strategies, and recent developments.

Technology Trends & Innovation: Analysis of emerging technologies in power management ICs, integration with IoT devices, and advancements in semiconductor fabrication processes.

Market Drivers & Restraints: Evaluation of factors such as growing demand for portable electronics, increasing adoption of IoT devices, and challenges related to supply chain constraints and raw material shortages.

Stakeholder Analysis: Strategic insights for component manufacturers, OEMs, system integrators, and investors regarding market opportunities and challenges.

Related Reports:

https://semiconductorblogs21.blogspot.com/2025/06/global-pecvd-equipment-market-size.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-embedded-sbc-market-trends-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-encoder-chips-market-driving.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-bluetooth-audio-chips-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/semiconductor-ip-blocks-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-dc-power-supply-for.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-high-voltage-power-supply-for.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-industrial-sun-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-consumer-grade-contact-image.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-non-residential-occupancy.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-standalone-digital-signage.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/12-inch-silicon-wafers-market-global-12.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-12-inch-semiconductor-silicon.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-extreme-ultraviolet-lithography.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-industrial-touchscreen-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-distributed-fiber-optic-sensor.html

0 notes

Text

What are the main components and parts of LED displays

LED display, this light and shadow magician that is ubiquitous in modern cities, attracts our attention from large billboards on the street to live broadcast screens in stadiums with its dazzling colors and clear images. But what "parts" does it consist of? Today, let’s unveil the mystery of LED displays and take a look at the “heart”, “brain” and “skeleton” behind it.

Glowing "pixels": LED light beads and modules

When it comes to LED displays, the most core is of course the "LED" itself. These tiny LED light beads, like independent pixel dots, form what we often call "LED modules" through matrix arrangements integrated on the PCB (printed circuit board). Let you learn about the LED display soft module in 5 minutes.

LED light beads: Although it is small, it is the core of the glowing light. It is made of semiconductor materials and can emit three basic colors: red, green and blue (RGB) after power on. Through different combinations of these three colors and brightness adjustment, tens of millions of colors can be presented. The packaging technology, brightness, viewing angle and life of the lamp bead directly determine the display effect and stability of the display screen. Here is Mini LED vs COB packaging: a technical choice from the user's perspective.

LED module: Multiple LED lamp beads are arranged at a certain spacing, soldered onto the PCB board, and then controlled by the driver IC to form an LED module. You can think of it as LEGO blocks, and modules of different specifications can be spliced into display units of various sizes. The flatness, consistency and protection level of the module (such as waterproof and dustproof) are crucial to the overall performance of the display.

Support and connection "skeleton": box

LED modules need a solid "home" to accommodate them, which is the "box". The box not only plays a supporting role, but also is responsible for fixing modules, power supply and heat dissipation.

Material: Common box materials include die-cast aluminum, sheet metal, carbon fiber, etc. Die-cast aluminum box is lightweight and has high precision, and is often used for rental screens; sheet metal box costs are relatively low and mostly used for fixed installation screens; carbon fiber box is popular in the high-end rental market for its ultra-light characteristics.

Structure: The box is designed with heat dissipation channels, power supply and signal interfaces. Good heat dissipation design can effectively extend the life of LED lamp beads and driver ICs. At the same time, the splicing accuracy of the box also directly affects the overall flatness of the display.

The "heart" of power supply: power supply

The light of the display screen cannot be separated from electrical energy, and the "power supply" is the one that provides stable and efficient electrical energy.

Type: LED displays usually use switching power supplies to convert mains into DC low voltage power required for LED lamp beads and drive ICs. Let you understand how LED light beads work.

Importance: The stability of the power supply, conversion efficiency, power factor and protection level (such as overvoltage and overcurrent protection) will affect the operating stability and life of the display. A good quality power supply can allow the display to work "healthily" for longer.

The "brain" of control and transmission: the control system

If the LED module is the "eye" of the display screen, then the control system is its "brain" and "nerve". It is responsible for receiving external signals and converting them into driving signals that the LED module can recognize, thereby realizing screen display.

Send card: Process the signals from the computer or video player and send them out via network cable or optical fiber.

Receive card (also known as driver card): installed inside the LED box, responsible for receiving signals from the transmission card and assigning them to each LED module. The number and performance of the received cards directly determine the refresh rate, grayscale level and screen display effect of the display.

Video processor: Displays that require complex processing such as playing high-definition video, multi-screen switching, and zooming, are usually equipped with professional video processors. It can uniformly process and optimize video signals in different formats to ensure smooth and clear pictures.

Control software: Professional software running on the computer, used to edit, manage playback content, set display parameters, etc.

The "blood vessel" that transmits signals: wire

What connects various components and transmits power and signals is a variety of wires.

Power cord: Responsible for power supply, and you need to choose a thickness that meets safety standards to ensure stable current transmission and no heating.

Signal line: transmits data signals, usually using network cables or optical fibers. High-quality signal lines can ensure the integrity and stability of signal transmission and avoid jittering, screen-flowing and other phenomena.

Fixed "support": steel structure

For large outdoor LED displays, a solid "steel structure" is also needed to support the weight of the entire screen and resist the invasion of natural forces such as wind and rain. The design and construction of steel structures require professional civil engineering knowledge to ensure the safety and stability of the display screen. Give you a steel frame LED screen: key features, case studies and buying tips.

Summarize

An LED display is the crystallization of the collaborative work of many precision components. From tiny LED lamp beads to huge steel structures, every link is crucial. Understanding these main components and their functions will not only help us better select and use LED displays, but also be clear about them in daily maintenance. The next time you see dazzling LED billboards on the streets, you may be able to see these "heroes behind the scenes"!

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: Full guide to renting indoor LED displays. Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

Festival of Lights - NeoRGB Stemma revision ✨🌈

We're doing 8 days of light-filled designs to wrap up this year. We started with the Sparkle Motion Mini

which can drive thousands of shimmering RGB LEDs. Then, we did the Sparkle Motion stick, a USB-pluggable version

On the third night, a 1.28" round TFT display

and on the fourth a 1.8" round TFT with captouch overlay

On the fifth night, a tiny 0.85" TFT display

came to life.

This night, we're taking a little bit of a breather since we want to do final testing and hopefully send out the Sparkle Motion PCBs

So, we're doing a quick revision of the NeoRGB Stemma board

This time, we're adding a level shifter so it can be used with 3.3V logic. It's just a small fix, but it will make the board a lot more usable!

#festivaloflights#neorgb#stemma#rgbleds#sparklemotion#tftdisplay#techdesign#adafruit#electronics#makers#diyelectronics#opendesign#pcbrevision#engineering#innovation#leddesign#creativeelectronics#makersmovement#lightshow#captouch#tftlcd#rounddisplay#logiclevelshifting#ledtech#ledart#tinytech#electronicsdesign#makercommunity#sparklinglight#technologyart

6 notes

·

View notes

Text

What is RoHS Certification in USA and why is it important?

What is RoHS Certification?

RoHS certification in USA is a reference to Restriction of hazardous substances. The RoHS directive was created in the European Union; the RoHS directive seeks to limit the use of harmful substances in electronic and electrical equipment.

The substances which are not allowed as defined by RoHS are:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent Chromium (Cr6+)

Polybrominated Biphenyls (PBB)

Polybrominated Diphenyl Ethers (PBDE)

Four Phthalates (DEHP, BBP, DBP, DIBP)

Is RoHS Mandatory in the USA?

The USA has no uniform national RoHS law. However, states such as California (through the Electronic Waste Recycling Act) and many other states have adopted ROHS consultant in USA-aligned regulations. Additionally, U.S. companies that export electronics to RoHS-regulated areas like those in the European Union, UAE, China, and India must adhere to ROHS consultant in USA rules to ensure market access.

The bottom line is that RoHS Certification isn’t only a nice thing to have, it’s frequently required by custo,ators, and ,foreign buyers.

Who Needs RoHS Certification in USA?

RoHS Certification is essential for:

OEMs (Original Equipment Manufacturers)

Electronics producers and assembly companies

Manufacturers of LED lighting and displays

Medical device producers

Brands of consumer electronics and appliances

Automotive electronics suppliers

Providers of network equipment and telecom services

If your product is equipped ROHS consultant services in USA with a PCB or power source plug, it is likely to need to be in compliance with.

Steps to Achieve RoHS Certification in USA

Factocert is an expert-led, streamlined approach to assist you with obtaining the following certifications:

1. Product and Material Review

Examine the BOM (Bill of Materials) and examine high-risk components or items.

2. Testing and verification

Co-operate with accredited ROHS consultant services in USA laboratories to conduct chemical testing.

3. document preparation

Create the Tech Construction File (TCF), test reports, MSDS, and supplier declarations.

4. Declaration of Conformity (DoC)

Draft and then sign your self-declaration, or get an independent RoHS certification.

5. Audit (Optional)

Conduct internal or third-party audits to confirm the product’s compliance and process.

Key Documents Required

Technical Construction File (TCF)

Supplier Declarations of Compliance

Test Reports from RoHS-certified labs

Material Safety Data Sheets (MSDS)

Declaration of Conformity (DoC)

Compliance Checklist

Timeline & Cost Factors

The ROHS auditor in USA certification timetable can vary from two to six weeks, depending on:

Complexity of the product

Data on technical availability

Lab testing requirements

Cost varies based on: cost is based on:

The number of models for products

Component/material diversity

Consulting and testing scope for labs

Factocert provides cost-effective RoHS solutions specifically tailored to small and medium-sized businesses and large-scale producers.

RoHS & Global Market Access

ROHS auditor in USA Certification is becoming more and more required to export products into:

European Union (EU RoHS 2)

China RoHS

UAE RoHS

India, Korea, and various other Asia-Pacific regions

If there is no RoHS compliance, shipments could be delayed, rejected, or even penalized. The certification process is an essential entry point for global trade.

Why Factocert for ROHS Certification in USA?

We provide the best ISO Consultants in USA who are knowledgeable and provide ISO 26000 consultant services in USA the best solutions. Kindly contact us at [email protected]. ISO Certification consultants in USA and ISO auditors in USA work according to ISO standards and help organizations implement ISO Certification with proper documentation.

For more information, visit ROHS certification in USA

0 notes